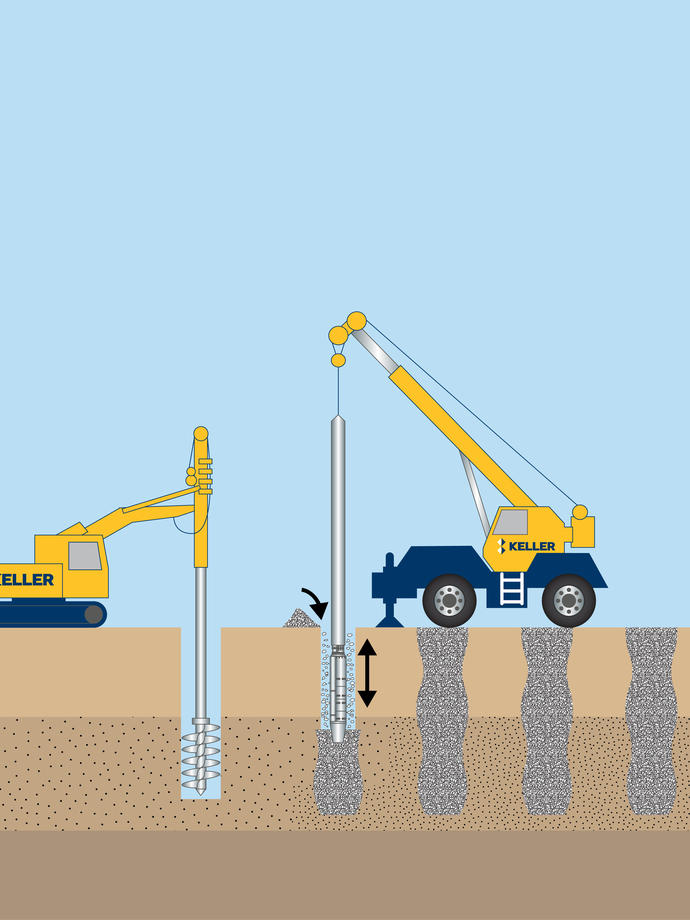

The process allows for construction flexibility and the ability to construct through caving zones that are encountered during drilling operations. Then as hollow mandrel is raised stone flows from hopper down through mandrel.

Pdf Rammed Aggregate Pier Design And Construction In California Performance Constructability And Economics Semantic Scholar

Rammed Aggregate Pier Construction.

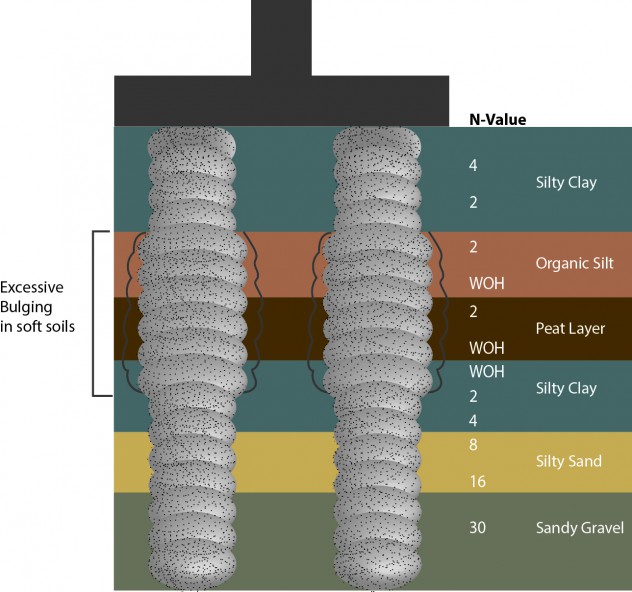

. The down-hole compactive device may be either a high-frequency vibratory probe or a vertical tamper. Soft silts and clays. Once at depth the mandrel is withdrawn several feet to allow open-graded aggregate to flow into the annular space.

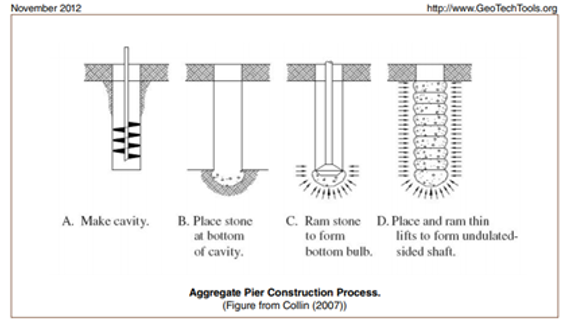

1 rammed aggregate pier construction process a. Although Terrapiers are similar to other aggregate columns such as the Geopier Rammed Aggregate Pier a vastly improved design methodology has been developed. Aggregate piers referenced in these specifications refer to both vibro stone columns and rammed piers.

The rankine passive earth pressure coefficient is calculated for the matrix soil and multiplied by the vertical effective stress to determine the. Ram 2 crushed rock into the bottom bulb c. Higher friction angles provide greater pier capacity which means fewer Geopier elements are required.

THE DPT shall be performed at locations within the upper 13 of the pier shaft and should be in general accordance with ASTM STP 399. V ibro piers also known as aggregate piers are typically in stalled to intermediate depths of 5 to 20 feet for the support of new loads. This displacement construction method can be used in a variety of soil conditions.

The soil profile is comprised of firm to stiff silty clay and medium dense silty sand of 10 m thickness overlain on thick soft to medium stiff silty clay with thin inclusions of sand lenses. Terrapiers are rammed aggregate columns acting as structural elements designed to reinforce a compressible soil mass allowing shallow foundation support with minimal settlement. Soils below the groundwater table.

Ram ¾ to 1½ crushed road base rock in 12 lifts up to the bottom of footing plus 6 to 12 the ramming equipment consists of a 45000 pound hydraulic excavator equipped with a 3500 pound hydraulic break. Temporary casing used to stabilize caving soils. One approach for estimating the uplift capacity of rammed aggregate piers is based on lien and fox 2001 and wissman and fox 2000the lien and fox 2001 procedure includes the following steps.

In 2016 Geopier quoted 300 Rammed Aggregate Piers 28 deep 30 diameter for 387000. The Geopier X1 system creates Rammed Aggregate Pier RAP elements using a vertical ramming process which is a combination of both replacement and displacement methods. Geopier X1 piers are constructed using a track-mounted auger to drill out unsuitable soils and a specialty mandrel mounted to a mast rig to construct the Rammed Aggregate Pier RAP elements.

Build Your Project from the Ground Up with Foundation Technologies. Rammed Aggregate Pier Construction. Each lift of stone or other granular material is compacted forming a high modulus aggregate pier.

Essentially by using a rammed aggregate pier system to increase the existing soils bearing capacity the structural engineer can design a shallow footing system that would typically be used for a site with preferred soil conditions. Ad Download Or emailstems Aggregate Piers More Fillable Forms Register and Subscribe Now. Principals in our firm are licensed Geotechnical engineers with extensive prior experience in Geotechnical analysis and design including 25 years of designbuild experience of the Geopier Rammed.

The specialty mandrel and larger equipment allows for significantly faster and cheaper pier construction. Typical Process Aggregate pier systems are fairly simple in nature to install. More info Services WGI offers ground improvement options to engineers contractors and developers in California Nevada New Mexico and Arizona.

Ad Chance Foundation Anchoring Tools Get the Job Done. They can be designed to meet specific improvement criteria and alternative methods of installation provide potential cost savings. More info About Us WGI is the regions leading design-build ground improvement contractor specializing in Geopier technologies.

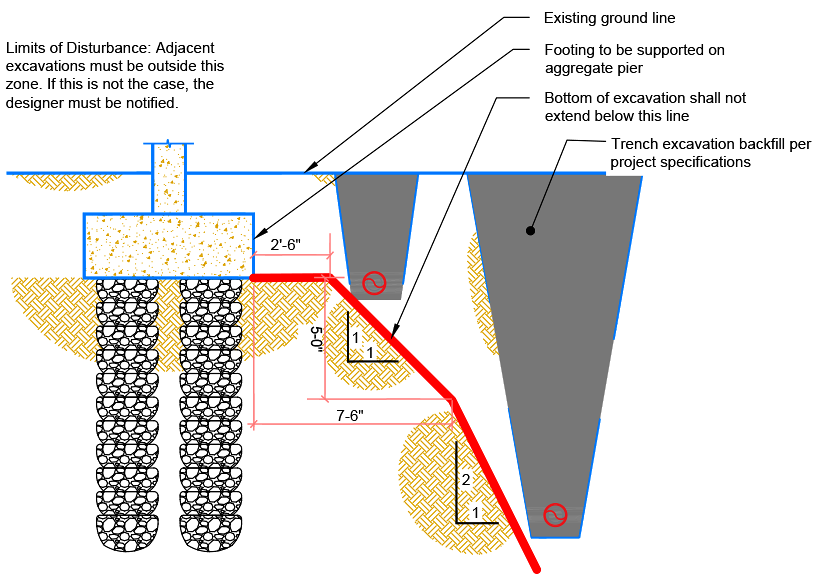

This Technical Bulletin discusses the design concepts for the structural design of strip footings supported by Rammed Aggregate PierRAP soil reinforcing elements. DESIGN OF STRIP FOOTINGS OVER SOIL REINFORCED BY RAMMED AGGREGATE PIERS. Turkey constructed on soils improved by the Rammed Aggregate Pier RAP System are presented.

The mandrel is then redriven to create a densified 2-foot-thick lift of aggregate. In addition we had 54000 of spoils removal. 421 The Dynamic Cone Penetrometer Test shall be performed on Rammed Aggregate Piers constructed using well-graded aggregate only.

GeoBase Dynamic Subgrade Improvement. Legal Forms Real Estate Power of Attorney Sales More. Design shall rely on subsurface information presented in the project geotechnical report.

Contaminated soil drove the disposal cost up to 36CY. Geopier Impact piers are installed by advancing a displacement mandrel through unsuitable soils to a desired design depth. The phrase aggregate piers may be used to describe either a rammed pier or a vibrated pier also called a vibro stone column VSC.

Our company specializes in the design and construction of the GeoRam Design Engineered Aggregate Pier EAP and. RAMMED AGGREGATE PIER DESIGN CALCULATIONS Rammed aggregate pier construction increases vertical and horizontal stresses in the matrix soil and increases the stiffness of soil and fill which significantly reduces foundation settlements Lawton and Fox 1994 Pitt et al. It is important that a structural engineer understand the installation and.

Suited for light to heavy loads on large or small projects vibro piers are quick to install and very effective at reinforc ing the surrounding soil. Conventional strip footings supported at grade are traditionally designed assuming that the subgrade soils. The ramming process produces the superior strength of a Geopier Rammed Aggregate Pier RAP and develops constructed aggregate friction angles greater than 48 degrees almost 40 greater than those reported for stone columns.

In high seismic and high wind zones the resistance to lateral and. Provision of all equipment material labor and supervision to design and install aggregate pier elements. The 48-hour load test plus footing cost 31000.

Chief among them are Geopier Rammed Aggregate Pier. Rammed aggregate piers are an innovative and cost effected method of ground improvement. Geopier Impact Rammed Aggregate Piers RAPs are a versatile ground improvement solution designed to reinforce poor soils through the use of a patented displacement mandrel.

Geopier Rammed Aggregate Pier Installation Cost. Aggregate in the upper portion of the Rammed Aggregate Pier. Drill 30 and 33 diameter rap shafts b.

Impact hammer After driven to full depth mandrel is raised up 3 ft Then driven back down 2 ft Dense 1 ft lifts Crowd.

Pdf Rammed Aggregate Pier Design And Construction In California Performance Constructability And Economics Semantic Scholar

Utilities With Ground Improvement

Pdf Rammed Aggregate Pier Design And Construction In California Performance Constructability And Economics Semantic Scholar

Aggregate Piers Filling The Gap Geo Hydro Engineers

Rammed Aggregate Pier Construction Process Download Scientific Diagram

0 comments

Post a Comment